This acoustic floor underlayment can improve the iic impact insulation class by up to 12 points over a wood frame and up to 20 points over concrete.

Acoustical membrane iso step floor underlayment.

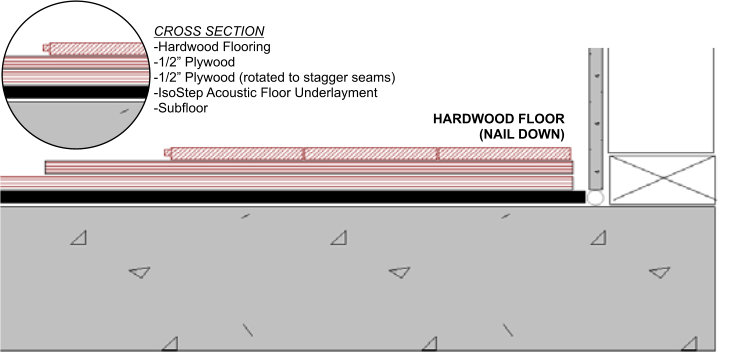

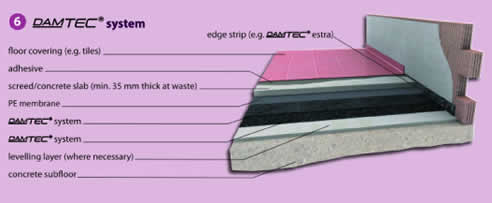

Acoustic underlayment special materials that lay over a concrete or plywood subfloor cushioning the flooring and reducing the effects of airborne and impact noise.

Acoustical solutions bears no responsibility for installation or contractor selection.

Manufactured in the usa using recycled material this rubber floor underlayment has been rigorously field tested.

Iso stepfloorunderlayment as iso step floor underlayment installation guide 2018 11 15 the following installation instructions are given as a general guide to avoid common errors.

It improves iic ratings impact insulation class by providing an impact resistant layer under flooring.

Iso step acoustic floor underlayment.

Iso step acoustic floor underlayment when installed correctly is a double duty acoustical underlayment.

Iso step floor underlayment re bonded recycled rubber sheet underlayment 2.

This reduces the transmission of structure borne sound.

Sound deadening vinyl also known as mass loaded vinyl this is a thin but heavy vinyl sheet that excels at dampening noise especially in floors machinery and vehicles.

Iso step polyethylene foam perimeter isolation strip 3.

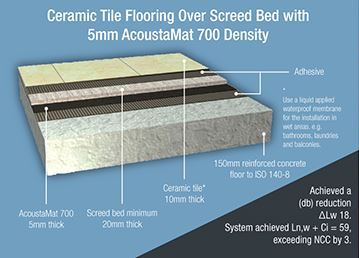

The acousti mat floor underlayment is used to increase sound isolation and reduce impact noise in wood concrete and steel deck construction assemblies.

See the definitions of stc and iic below.

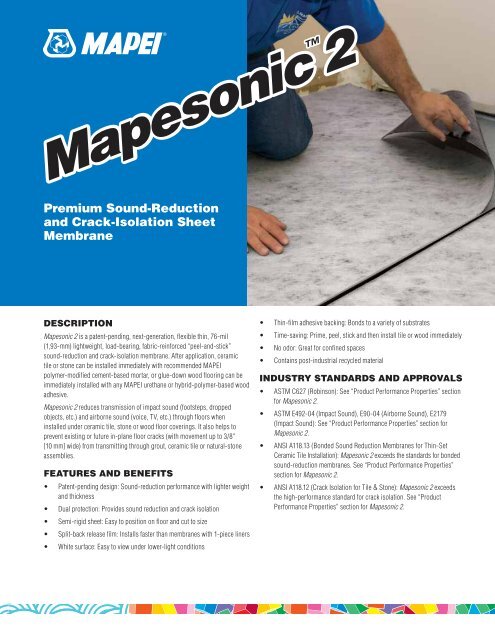

170 5 sound crack isolation mat is a high performance anti fracture sound and crack isolation membrane designed to be used under thin bed adhesive for interior floor installations of ceramic tile marble stone and brick to reduce the transmission of impact noise and help provide soundproofing between floors and isolate cracks in the substrate.

Iso step rubber impact sound insulation and accessories supplied by acoustical solutions.

Acoustic underlayment is mainly used to increase iic ratings in floors read comparing sound ratings with the many different acoustic floor underlayment products there seems to be some debate on which material works best in floors as well as the legitimacy of the floor underlayment ratings for these products.

Installer should follow best practices for construction and workmanship.

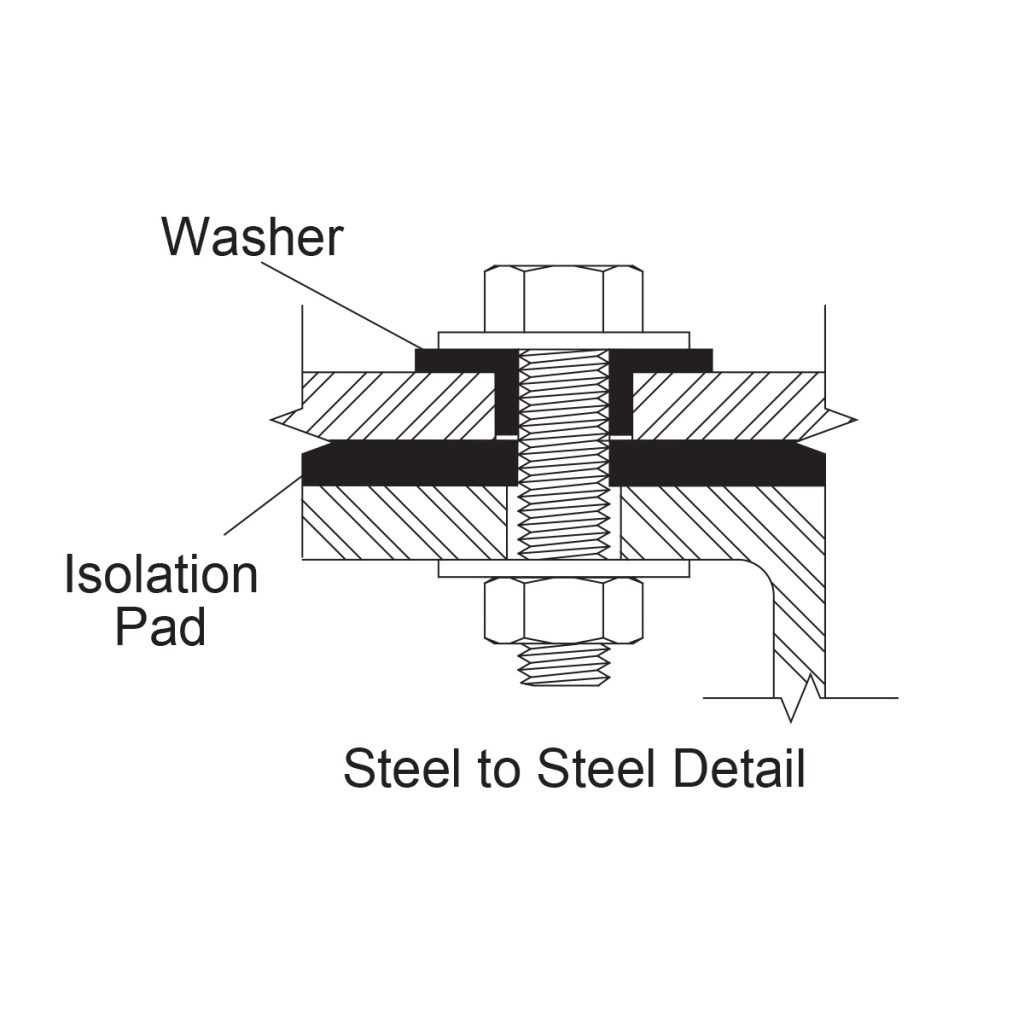

This provides an isolation layer to help prevent structural sound from passing through the completed assembly.

E grip iii a one component polyurethane adhesive 4.